Knife Durability: What It Means for Damascus Steel

Most American culinary professionals know the frustration of seeing a prized kitchen knife lose its edge after just a few months. Durability is not just a buzzword in knife selection—it determines how consistently you can perform at a high level in the kitchen. While Damascus steel knives offer up to 30 percent longer edge retention than conventional blades, many cooks misunderstand what truly influences longevity. This guide helps you separate fact from fiction so you can select and maintain knives built to last.

Table of Contents

- Defining Knife Durability And Common Misconceptions

- Knife Durability By Steel Type And Construction

- Key Characteristics Affecting Blade Longevity

- Damascus Steel Advantages For Lasting Performance

- Practical Risks, Maintenance, And What To Avoid

- Comparing Knife Durability Across Alternatives

Key Takeaways

| Point | Details |

|---|---|

| Understanding Knife Durability | Knife durability is influenced by material composition, manufacturing techniques, and maintenance practices. Harder steel does not always equate to superior durability. |

| Significance of Damascus Steel | Damascus steel offers exceptional performance through its multilayered construction, balancing hardness and flexibility for lasting use. |

| Critical Maintenance Practices | Proper care, including avoiding moisture exposure and using appropriate cleaning methods, is essential for preserving the integrity of high-performance knives. |

| Steel Type Comparisons | Different steel types offer unique characteristics; selecting the right one depends on specific culinary needs and maintenance capabilities. |

Defining Knife Durability and Common Misconceptions

Knife durability represents more than just a blade’s ability to resist wear. It encompasses the blade’s capacity to maintain its structural integrity, sharpness, and performance under repeated use across various cutting conditions. Professional chefs and serious home cooks understand that durability is a complex interplay between material composition, manufacturing techniques, and maintenance practices.

In the culinary world, knife durability is often misunderstood. Many people mistakenly believe that a harder steel automatically translates to superior durability. However, knife sharpness research reveals that mechanical properties are far more nuanced. Damascus steel, renowned for its distinctive pattern and exceptional performance, demonstrates that durability involves a delicate balance between hardness, flexibility, and edge retention.

Common misconceptions about knife durability include assuming that all high-end knives will maintain their edge indefinitely or that frequent sharpening automatically improves performance. In reality, proper maintenance, understanding the blade’s metallurgical characteristics, and using appropriate cutting techniques are crucial. Damascus steel knives, with their multilayered construction, require specific care to preserve their unique properties and ensure long-term performance.

Pro tip: To maximize your Damascus steel knife’s durability, invest in a high-quality ceramic honing rod and use it regularly at a consistent 15-20 degree angle to realign the blade’s edge without removing significant metal.

Knife Durability by Steel Type and Construction

Damascus steel represents a pinnacle of knife durability, combining complex metallurgical engineering with centuries of craftsmanship. Unlike standard steel types, Damascus steel’s distinctive layered construction provides unique performance characteristics that go far beyond simple hardness measurements. Knife steel durability research demonstrates that material selection plays a critical role in determining a blade’s overall performance and longevity.

The inherent strength of Damascus steel emerges from its multilayered forging process, where multiple steel types are repeatedly folded and welded together. This technique creates a blade with exceptional structural integrity, combining softer, more flexible steel layers with harder, more wear-resistant core metals. Professional knife makers understand that durability isn’t just about hardness, but about creating a balanced composition that can withstand diverse cutting conditions while maintaining a sharp, resilient edge.

Different steel types offer varying durability profiles, which become crucial when selecting knives for specific applications. High carbon steels provide excellent edge retention, while stainless steel variants offer superior corrosion resistance. Comprehensive steel analysis reveals that no single steel type represents a universal solution, emphasizing the importance of matching blade material to intended use. Damascus steel’s unique construction allows it to blend multiple steel characteristics, creating a knife that performs exceptionally across various culinary and professional environments.

Pro tip: When evaluating knife durability, focus not just on the steel type, but on the blade’s overall construction, including how different metal layers are integrated and the precision of the forging process.

Key Characteristics Affecting Blade Longevity

Blade longevity is a complex interplay of material science, manufacturing techniques, and ongoing maintenance. Professional chefs and knife enthusiasts understand that a knife’s durability extends far beyond its initial sharpness, encompassing its ability to maintain performance under repeated stress and challenging cutting conditions. Material science innovations reveal the intricate factors that determine a blade’s true resilience.

Several critical characteristics directly influence a knife’s long-term performance. Hardness represents the blade’s resistance to deformation, typically measured on the Rockwell hardness scale. Toughness describes the steel’s ability to absorb energy without fracturing, which is crucial for knives experiencing varied cutting environments. Corrosion resistance prevents degradation from moisture and acidic foods, while wear resistance determines how well the blade maintains its sharp edge through repeated use. These qualities are not independent but interconnected aspects of a knife’s overall durability.

The manufacturing process plays a pivotal role in determining blade longevity. Heat treatments like quenching and tempering fundamentally alter the steel’s molecular structure, enhancing its mechanical properties. Precise thermal processing can improve a blade’s ability to withstand repeated stress, resist chipping, and maintain its cutting edge. Professional knife makers carefully balance these techniques, understanding that optimal durability requires a nuanced approach that goes beyond simple material selection.

Here is a summary of key factors impacting blade longevity and their effect:

| Longevity Factor | Positive Impact | Negative Impact |

|---|---|---|

| Heat Treatment | Enhances structure | Poor control causes brittleness |

| Corrosion Resistance | Extends blade life | Low resistance enables rust |

| Edge Retention | Fewer sharpenings | Soft steel loses sharpness fast |

| Toughness | Prevents chipping | Too hard leads to fractures |

Pro tip: Invest in a professional blade assessment every two years to evaluate your knife’s structural integrity, checking for microscopic wear patterns that might compromise its long-term performance.

Damascus Steel Advantages for Lasting Performance

Damascus steel represents a pinnacle of metallurgical engineering, offering unique performance characteristics that set it apart from conventional knife materials. Genuine Damascus steel research reveals a sophisticated manufacturing process that combines multiple steel layers to create exceptional blade performance. The intricate layering technique produces a knife that is simultaneously strong, flexible, and remarkably resilient, making it a preferred choice for professional chefs and knife enthusiasts.

The multilayered construction of Damascus steel provides significant mechanical advantages. By combining different steel types like AISI 1095 and 15N20, these knives achieve a remarkable balance between hardness and toughness. The alternating layers create a blade that can withstand significant stress without fracturing, while maintaining an incredibly sharp cutting edge. This unique structure allows the knife to redistribute stress across multiple layers, reducing the likelihood of chipping or catastrophic failure during intense cutting tasks.

Professional knife makers prize Damascus steel for its ability to deliver superior performance across diverse culinary environments. The blade’s complex structure provides enhanced wear resistance, meaning the knife maintains its sharpness longer than traditional single-metal blades. While the steel can be susceptible to corrosion if not properly maintained, its extraordinary strength and enduring sharpness make it a top choice for those seeking high-performance cutting tools. The careful heat treatment and precise folding techniques transform raw materials into culinary instruments of exceptional quality and longevity.

Pro tip: Protect your Damascus steel knife’s unique layered structure by using a specialized cutting board and avoiding harsh cleaning methods that could compromise its intricate molecular composition.

Practical Risks, Maintenance, and What to Avoid

Damascus steel knives, while exceptional in performance, require nuanced care to preserve their unique characteristics. Professional chefs and culinary enthusiasts must understand the specific maintenance challenges associated with these high-performance blades. The intricate layered structure that provides strength and flexibility also demands more sophisticated maintenance strategies compared to standard kitchen knives.

Several critical risks can compromise a Damascus steel knife’s integrity. Moisture exposure represents the most significant threat, potentially initiating corrosion between the intricate steel layers. Acidic foods, prolonged contact with salt, and improper cleaning techniques can accelerate metal degradation. Professional knife handlers should avoid storing knives in damp environments, immediately clean and dry the blade after use, and prevent extended contact with corrosive substances. Mechanical risks include using inappropriate cutting surfaces that can damage the delicate edge or misaligning the blade’s molecular structure through improper sharpening techniques.

Maintenance requires a systematic approach tailored to Damascus steel’s unique composition. Knife maintenance techniques emphasize gentle hand washing, immediate drying, and periodic application of food-grade mineral oil to protect the blade’s surface. Avoid dishwashers, harsh chemical cleaners, and abrasive cleaning materials that can compromise the knife’s intricate layered structure. Professional sharpening should be performed by experts familiar with Damascus steel’s specific metallurgical characteristics to maintain the blade’s exceptional cutting performance.

Pro tip: Store your Damascus steel knife in a dry wooden block or magnetic strip with soft padding, ensuring minimal contact with other metal surfaces to prevent potential corrosion and structural stress.

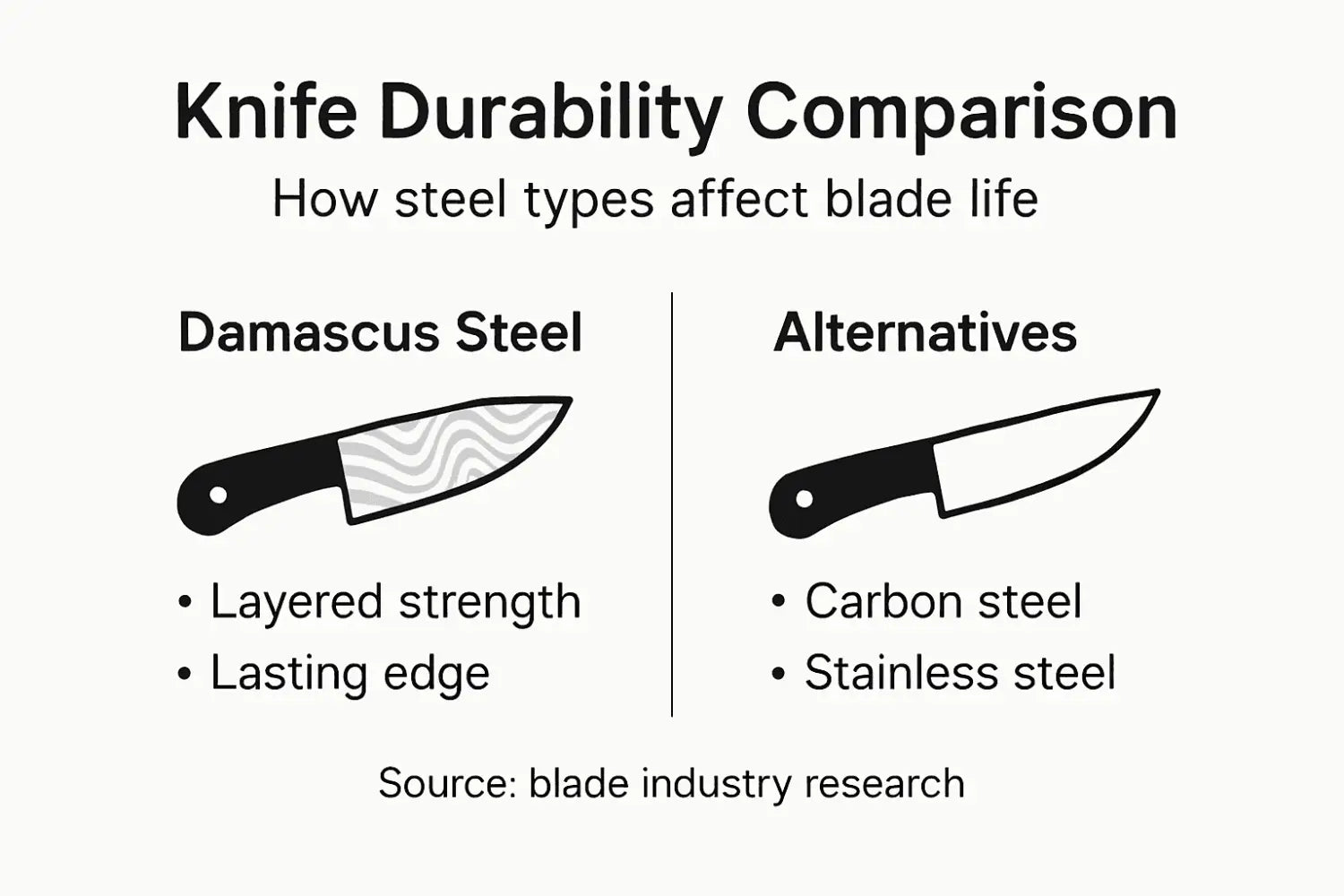

Comparing Knife Durability Across Alternatives

Knife durability is not a one-size-fits-all characteristic, with different steel types offering unique performance profiles tailored to specific culinary and professional needs. Comprehensive steel comparison reveals that each material brings distinct strengths and limitations to the cutting experience, making material selection a critical decision for serious knife users.

Carbon steel, stainless steel, and tool steels represent the primary alternatives to Damascus steel, each with characteristic durability attributes. Carbon steel offers exceptional edge retention and ease of sharpening but remains vulnerable to corrosion. Stainless steel provides superior rust resistance and moderate durability, making it popular for everyday kitchen use. Tool steels, known for extreme hardness, excel in high-stress cutting environments but can become brittle under certain conditions. Damascus steel distinguishes itself by combining multiple steel types, creating a blade that balances hardness, flexibility, and wear resistance more effectively than single-metal alternatives.

Below is a comparison of the main steel types used for knife durability and their core strengths:

| Steel Type | Strengths | Typical Weaknesses | Best Use Cases |

|---|---|---|---|

| Damascus Steel | Balanced hardness, flexible | Requires special care | Professional culinary tasks |

| Carbon Steel | Superior edge retention | Prone to corrosion | Precision slicing, chefs |

| Stainless Steel | High rust resistance | Moderate edge retention | Everyday kitchen use |

| Tool Steel | Extreme hardness | Can become brittle | Heavy-duty/professional use |

The selection of knife steel depends on nuanced performance requirements. High-carbon steels deliver remarkable sharpness and edge retention but demand meticulous maintenance. Powder metallurgy steels represent cutting-edge technology, offering unprecedented uniformity and performance characteristics. Damascus steel emerges as a premium option, leveraging multilayered construction to mitigate individual steel limitations and provide a more resilient, adaptable cutting instrument that performs consistently across diverse culinary scenarios.

Pro tip: When comparing knife durability, prioritize your specific usage requirements over generalized performance metrics, understanding that the most expensive or technically advanced steel may not always represent the best solution for your individual needs.

Elevate Your Culinary Experience with Unmatched Damascus Steel Durability

Understanding the true meaning of knife durability, especially in premium Damascus steel, reveals how crucial balanced hardness, toughness, and proper care are to lasting blade performance. If you seek a knife that combines artisan craftsmanship with exceptional structural integrity and edge retention, your search ends here. At Faneema Cutlery, we specialize in handcrafted Damascus steel knives that embody everything discussed in this article: multilayered forging, precise heat treatment, and superior wear resistance designed for discerning chefs and culinary enthusiasts.

Explore our curated collections of chef knives, utility knives, and specialty blades crafted to deliver consistent sharpness and resilient performance even under rigorous use. Take advantage of our expert craftsmanship and unique metallurgy by visiting Faneema Cutlery today to invest in a blade built for both everyday cooking and demanding professional tasks. Discover the perfect balance of durability and elegance that only our Damascus steel knives provide and experience the difference now.

Frequently Asked Questions

What factors contribute to the durability of a Damascus steel knife?

Knife durability in Damascus steel is influenced by material composition, the multilayered forging process, and proper maintenance practices. Factors like hardness, toughness, and corrosion resistance play critical roles in determining a blade’s overall performance and longevity.

How does Damascus steel compare to other types of knife steel in terms of durability?

Damascus steel combines multiple steel types, offering a balance of hardness, flexibility, and wear resistance. In comparison, carbon steel provides excellent edge retention but is prone to corrosion, while stainless steel offers rust resistance with moderate durability. Tool steels excel in extreme hardness but can become brittle under stress.

What maintenance practices are essential for preserving Damascus steel knives?

To maintain Damascus steel knives, wash them gently by hand and dry immediately after use. Apply food-grade mineral oil periodically to protect against corrosion, and avoid harsh chemicals or abrasive cleaning materials that could damage the blade’s unique structure.

Can a Damascus steel knife lose its sharpness over time, and how can I address this issue?

Yes, a Damascus steel knife can lose its sharpness over time due to regular use. To address this, use a high-quality ceramic honing rod regularly and maintain a consistent sharpening angle of 15-20 degrees to realign the blade’s edge and extend its longevity.

Recommended

- Choosing a selection results in a full page refresh.